Prompt feedback and iterations

One of the main advantages of the rapid prototyping process is that it delivers feedback on product design in no time. 3D printing, one of many rapid prototyping techniques, can create a working prototype in a matter of hours or days rather than weeks using traditional methods. Design and engineering to quickly test ideas and iterate on the fly. In one example, a prototype of a common automotive part could be created and tested within a matter of days, literally, the shape of the part being altered in hours on the basis of the results of real-world testing. A fraction of the cost of traditional manufacturing iterative rounds of feedback can be completed in house and within days, not months.

Reduced Time to Market

This shortens the prototyping phase, and time-to-market is of the essence in businesses where the first to market is the first in line for market leadership. Companies can now craft product designs and begin production promptly, thanks to the capacity to prototype quickly. Decreasing time to market by a few weeks is not only whatever in extremely competitive markets (technology, and consumer electronics) it can represent serious growth in terms of competitive advantage and additional revenue. Rapid prototyping can speed time to market as well — e.g., companies using rapid prototyping have claimed cuts to the time to product launch of 25% to 50% or more which could lead to revenue sooner.

Cost Savings

Large cost savings as well thanks to rapid prototype production This method allows organizations to escape the expensive errors that would only manifest themselves during full-scale production by detecting design issues as early as the design process. The cost of fixing issues in the design process can be as much as ten times cheaper to address after a product is prototyped, relative to changes made later on in production. Most of the materials used in rapid prototyping methods are additive in nature and more can be employed, so potential waste will be reduced and material costs will be lesser.

Enhanced Collaboration

It promotes better team collaboration; through rapid prototyping, every party involved in the project can better understand the requirements of the design to avoid mixing up of tasks. Rapid creation fast production of prototypes mean that they can be reviewed simultaneously by both design, engineering and manufacturing teams. This is good for your users, because it means that getting them in the room together is likely to result in the surfacing of potential optimizations and solutions that none of them would have realised alone. Having a physical model to look and break gives non-technical stakeholders a tactile feel for the final product and helps improve alignment across the project.

Customization Opportunities

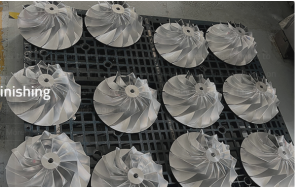

Rapid prototyping is great for higher level of customization, it is widely used within the medical equipment and aerospace industry where specific solutions may be required. Fast prototype turnaround means more iterations with bespoke designs to test and refine, and ultimately getting a final product that addresses targeted user needs or technical constraints of a particular project.

Increased Overall Efficiency

Together, iteration of rapid prototyping can indeed bring about efficiency improvements. Faster design verification, shorter development timelines, financial savings, improved collaboration, and customization allow businesses to facilitate the entire development process. Not only does it reduce costs through a systemic effect, it also automatically improves product quality and customer satisfaction

To summarize, rapid prototyping has brought about a revolutionary way of optimizing product development cycles by speeding up the process in varying industries. Today, in a time in which market conditions are rapidly changing, rapid prototyping allows immediate feedback, a reduction in time to market, a decrease in costs, an increase in collaboration, and extensive customizing.